Crane Component FAQ

This FAQ answers some common questions about crane components. We advise that you read this FAQ before downloading your guide.

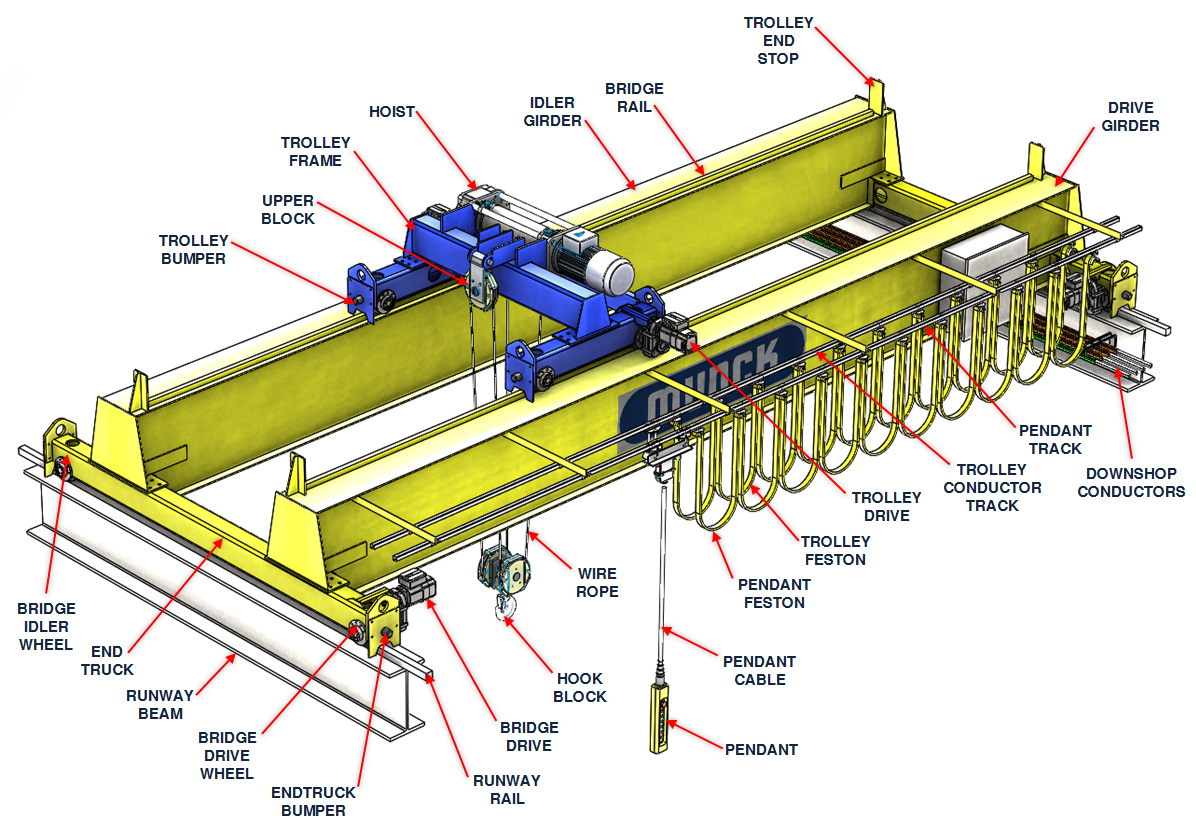

A bridge crane typically consists of the bridge, end trucks, girders, trolley, hoist, and a control system, among other smaller components. Each part plays a crucial role in the crane's overall function.

The girder provides the structural support needed for the trolley and hoist, allowing them to move across the crane's span.

End trucks are positioned on either side of the crane span and house the wheel assemblies, enabling the crane to move along its designated path.

Wire rope hoists are generally used for heavier lifting and are more durable, while chain hoists are more suitable for lighter loads and are typically more cost-effective.

The trolley moves along the girder and carries the hoist, which lifts and lowers the load.

Crane controls can vary, ranging from pendant stations to wireless radio controls and more sophisticated control panels with automation capabilities.

Common safety features include overload protection, limit switches, and emergency stop functions.

Inspection schedules can vary based on usage, but frequent checks for wear and tear are advisable, along with periodic in-depth inspections by qualified personnel.

Temperature, humidity, and corrosive environments can all impact the longevity and functionality of crane parts.

Many suppliers offer customization options for specific components to suit your operational needs.

Load capacity, lifting speed, and duty cycle are key factors to consider when choosing a hoist.

The rope drum is where the wire rope is wound, aiding in the lifting and lowering actions of the crane.

Signs like increased noise, decreased performance, and visible wear and tear can indicate that a component may need to be replaced.

For high-quality, reliable crane components, you can click our crane parts page.