Munck Cranes has a variety of solutions for all your material handling needs, from large capacity overhead bridge cranes, gantry and semi-gantry cranes to a full line of safe, reliable, high capacity jib cranes and extensions. Our MCI line of jib cranes are built to an exacting specification, easily meeting all of the current design and engineering regulations for quality, reliability and safety.

Jib cranes, or folding jib cranes are an ideal solution for light or heavy duty material handling in a defined space, allowing operators to manage a wide variety of materials within a defined circular or semi-circular processing zone, dependent on how the Jib is mounted.

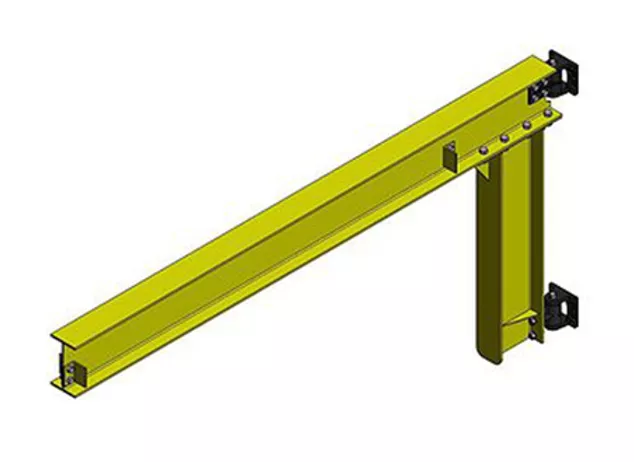

Wall or column mounted jib cranes are an elegant, cost effective and reliable material handling solution without a requirement to add additional columns or footings during install. The Munck Cranes team is eager to assist you in selecting or customizing the ideal jib crane solution to align with your application and building requirements.

This solution can be attached to either your building columns or directly to the building wall. A wall mounted jib crane, often called a Foundationless jib crane, does not consume valuable floor space, nor does it require footings or potentially expensive foundation work.

Benefits of a column mounted jib crane include exceptional boom clearance and they can be collapsed to avoid interference for other overhead cranes and equipment in your facility.

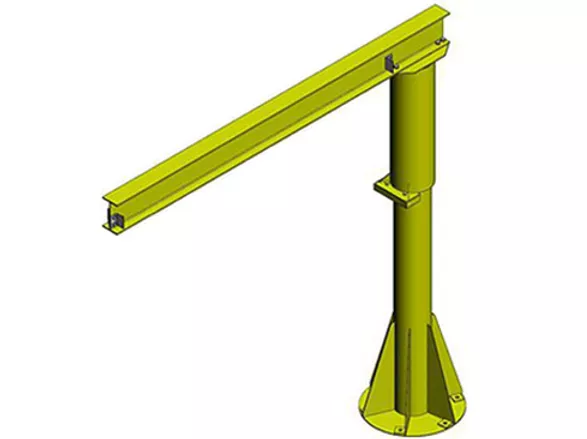

Unlike the wall/column mounted style, free standing jibs require footings and a strong foundation as they are independent structures from the building. This independence allows a free standing jib crane to be installed anywhere in your facility with sufficient space.

The free standing jib crane design allows for a greater capacity range and also for a longer boom span compared to the wall / column mounted jib solution. If you are interested in installing a jib crane on the exterior of your facility, all of our solutions can be ruggedized for outdoor use.

A cantilever jib crane is a hoisting crane with a swing or fixed cantilever (a long projecting beam or girder fixed at only on end, along which a hoisting trolley moves). Cantilever cranes are used primarily in shops of industrial enterprises and in closed warehouses. Load capacity of cantilever cranes ranges from 4 Tons to 10 Tons.

A Cantilever jib crane eliminates the need for a 'stringer support', meaning they will maximize the available headroom and are especially useful when there are existing overhead cranes.

Other Jib Crane configurations include:

Some standard uses for jib cranes include:

Before You Invest in Material Handling Equipment, Talk to Munck Cranes!